Our Process

Sourcing

To have the best chocolate, you need to start with the absolute best ingredients.

We source high quality cacao beans from awarded producers around the world. Along the Andes from Ecuador, Colombia and Peru, all the way to Tanzania and Madagascar.

The cacao pods are picked at their ideal point of maturation. Inside is a string of cacao seeds surrounded by a delicious white mucilage. The beans are fermented, typically in wooden boxes for 4-7 days depending on the natural climate. Once an even fermentation has undergone, the cacao is then dried, sorted and shipped to us.

We know who made it, the steps involved and how it was made, and most importantly, how much the producer was paid.

Roasting

We slowly and carefully roast our cacao in house, batch by batch, to ensure the flavour profile is the best it possibly can be.

The flavour of the chocolate greatly changes depending on the varietal of cacao, soil, fermentation and time the beans have been in Australia.

The roast is something we can control on our end. Lighter roasts maintain the fruity, floral characteristics of the cacao. Darker, bolder roasts develop the sugars to make the chocolate taste rounded and caramelised.

We roast on a 5kg Renegade coffee roaster, first installed in the iconic St. Ali in 2005. This roaster was responsible for bringing some of the best microlots of coffee to Australia. To this day it roasts some of the best small batches of cacao in Melbourne, if not the Southern Hemisphere / Galaxy.

Winnowing

Once the cacao has been roasted to its full potential, the beans need to be cracked into two parts: husk and nib. Think of a nut in its shell.

The outer shell is called the husk, which must be removed. We collect the husks to be repurposed in beer, baking and various other avenues.

The beautiful nibs are then extracted to be processed into chocolate.

Pre-refining

Our nibs are then passed between two stone rolling pins. With each pass the stone wheels gradually move closer, pressing the nibs together into flat ribbon-like sheets. Just like making pasta.

This is vital, making the nibs easier to process and saving us hours of milling time.

The smell is incredible as the cacao breaks down and the aroma is released.

Milling & Conching

This steel barrel is filled with thousands of small, food grade ball bearings. The centre shaft has arms that rotate the balls, creating friction and grinding anything that passes through the mosh pit.

As the nibs fall to the bottom of the mill, their texture refines from a grainy, cornflake-like texture to something that resembles a chunky peanut butter. The cacao naturally contains 45-50% of cocoa butter, which makes it melt. When ground down it becomes a thick, pasty liquid.

A pump transports the product back to the top, so it can continually be milled and reduced to the ideal texture. Here it becomes chocolate.

Depending on our recipe, organic sugar and cocoa butter are added to create varying percentages of chocolate. For example, our 60% Ecuador bar contains 60% nib and 40% sugar and cocoa butter.

It's then passed onto a conche, where an emulsifier blends the multiple batches together to create a uniform product.

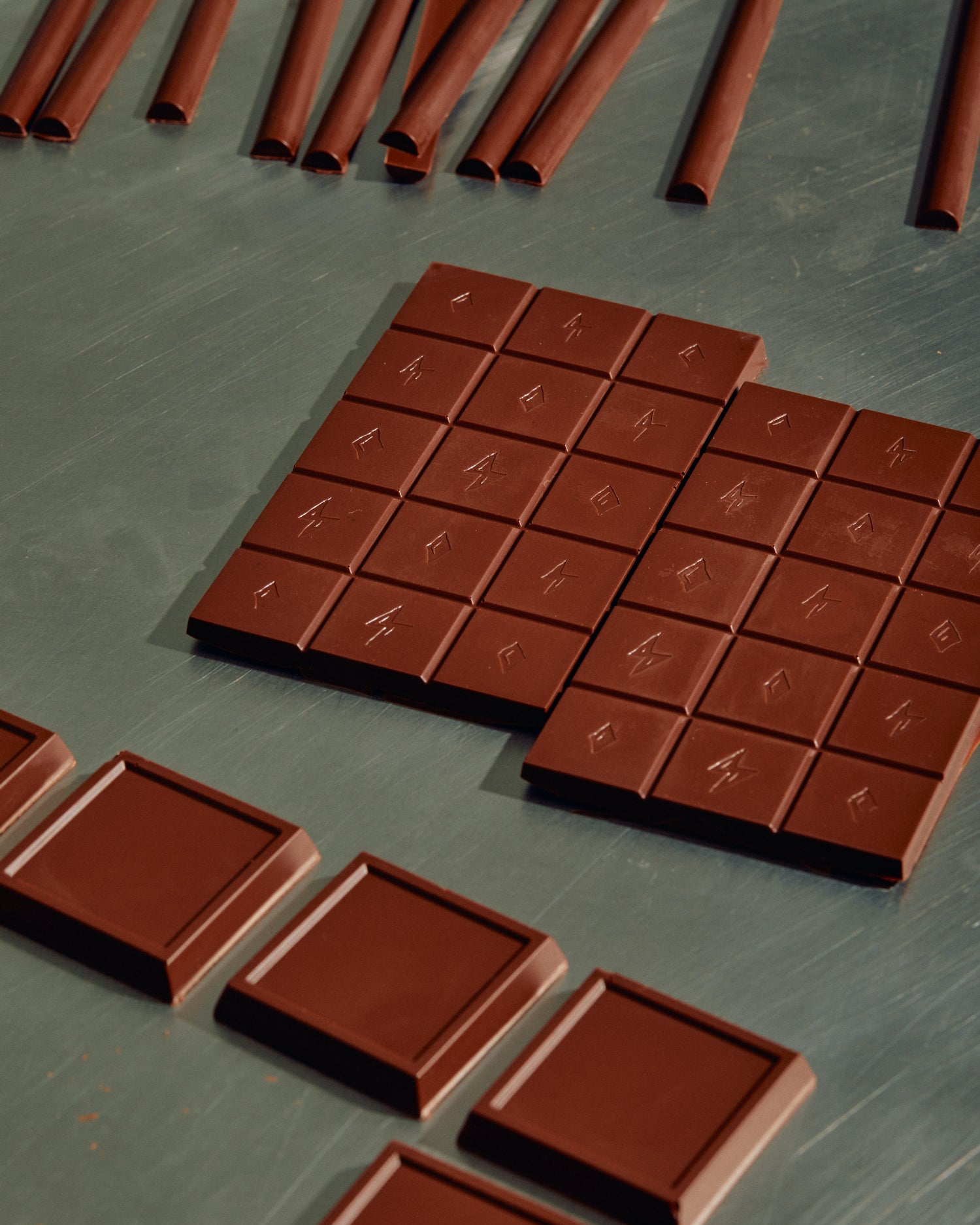

Tempering

Our chocolate needs to be shelf stable. Cocoa butter needs to be melted to the point where it is liquid or formless. It's then cooled down to the point where it crystallises and forms the right structure to hold the solids together.

This is a very sensitive step of the process. The room ideally needs to be around 18-24°c, the chocolate needs to be heated to a temperature (not too hot), cooled down to the right temperature (not too cold), then brought back to room temperature.

When we temper, we are trying to set the cocoa butter and create the right crystal formation. We are looking for a bar that can be held without melting, has a brilliant sheen and is tough like a CD case. If it isn't tempered properly it will melt immediately and look cloudy or even mouldy.

This is cocoa butter or sugar appearing on the surface. Imagine a brick wall with wet mortar. If you put pressure on the wall... the mortar will push out to the surface, the bricks will sink togerhter, it will look ugly and will no longer be structurally sound. This is the same as chocolate. We need the right crystal forms to be working together to form the structure of the bar.

Consuming

Once we have packed the bars, spreads, sauces or shavings, they are sent to you.

The cacao has travelled a long way to get to this stage. A lot of work has gone into it - and this is the most important step of all.

Sit down, and enjoy this precious moment. Let it melt, and appreciate the flavours.